MANAGEMENT SAFETY STATEMENT

This strategy document defines the AQUA ZONE Golden Rules to provide safe and healthy workplaces by preventing work-related injury and ill health.

The basic reference is the IOGP life-saving rules extended not only to life saving requirements but also to employees’ health. Environmental, social and governance issues not directly related with employees’ integrity are not addressed as Golden Rules and left to the Integrated Management System through the usual procedures.

The foundation stone of all the Golden Rules is that safety matters to everyone. Moreover, according to API definitions, workers have a personal responsibility to assure the safety of themselves and those around them.

They should STOP WORK at the jobsite if they think the working conditions or behaviors are unsafe (Stop Working Authority; SWA). The basic principles of SWA are:

- Safety is and will always be the primary focus.

- As part of the AQUA ZONE organization, you have a duty to work in a safe manner.

- You have a personal responsibility to assure the safety of yourself and those around you.

- Safety and safe practices should always be forefront when carrying out your job functions.

- All workers have “stop work authority”.

- Stop and ask questions when in doubt about the safety of any operations.

- Stop work at the jobsite if the working conditions or behaviors are considered unsafe.

- If you are discouraged from exercising the “stop work authority” or are penalized for doing so, report this action to management immediately

8 - Safety GOLDEN RULES

Protect Yourself and Others

Chemical Safety

Lockout-Tag out (LOTO) Procedures

Water Contamination Controls

Adhere to Electrical Safety

Operate Equipment Safely

Lifting & Handling Safety

Report Hazards and Incidents

1. PROTECT YOUR SELF AND OTHER

Always wear appropriate personal protective equipment (PPE) for the task, such as gloves, masks, and goggles.

.

Report any unsafe conditions or behaviors immediately to prevent

incidents.

Maintain a clean and organized workspace to reduce slip, trip, and fall

hazards

2. CHEMICAL SAFETY

Handle all chemicals according to safety guidelines, using proper labeling and storage procedures.

Follow Material Safety Data Sheets (MSDS) and avoid any unauthorized mixing of chemicals.

Use secondary containment for chemical storage and ensure disposal is in line with environmental regulations

3. LOCKOUT-TAG OUT (LOTO)

Before maintenance or repair work, isolate energy sources and use lockout-tagout devices to prevent accidental startup.

Only authorized personnel should operate lockouttagout equipment.

Verify equipment is fully de-energized before beginning work.

4. WATER CONTAMINATION CONTROLS

Handle waste responsibly, avoiding any discharge into untreated water sources.

Perform regular inspections and maintenance on purification equipment to prevent leaks or contamination.

Follow protocols to contain and clean any spills immediately.

5. ADHERE TO ELECTRICAL SAFETY

Only trained personnel should work on electrical installations or equipment.

Never operate equipment with damaged cords or connections, and report any faulty equipment.

Maintain a dry area around electrical equipment, particularly in water treatment zones.

6. OPERATE EQUIPMENT SAFELY

Only trained employees should operate purification and filtration

machinery.

Conduct regular maintenance checks and report any malfunctioning equipment immediately.

Never bypass or disable safety devices on any machinery or equipment

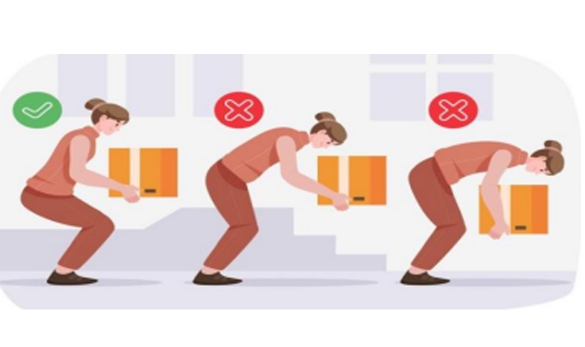

7. LIFTING AND HANDLING SAFETY

Use proper lifting techniques and seek assistance with heavy loads to avoid injury.

Use mechanical aids where possible, especially when handling chemicals or large water containers.

Follow ergonomic best practices for tasks requiring repetitive movements

8. REPORT HAZARDS AND INCIDENTS

Reporting hazards or incidents right away allows the team to address and rectify potential risks, preventing similar incidents from occurring in the future.

Immediate reporting fosters a culture where safety is prioritized, and everyone feels responsible for

Rapid reporting enables swift action, minimizing potential damage or injury and ensuring that corrective measures are implemented as soon as possible.